Transforming Materials with Heyl Patterson Rotary Calciners: Precision, Efficiency, and Versatility

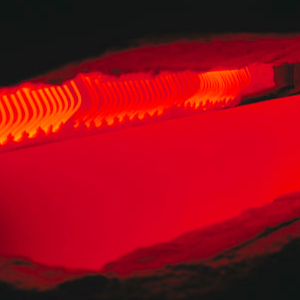

Heyl Patterson Rotary Calciners process hundreds of fine and dusty materials sensitive to oxidation, combustible, explosive, potentially contaminating, or thermally sensitive. Guaranteeing complete segregation of the heat source and the product through indirect heating, the Heyl Patterson Rotary Calciner is ideal for processing catalysts, chemicals, hydrocarbons, activated carbon, yellowcake, and PET flakes, as well as for biomass torrefaction or carbonization. Built to your unique specifications or designed by our engineers to exceed your application requirements, each Heyl Patterson Rotary Calciner can be rigorously tested at our Pilot Plant Testing Facility before the final design is implemented.

We also offer Fluid Bed Calciners for our customer’s other specifications.

Specifications for a Rotary Calciner can be customized to a customer’s particular application, including:

- Sizes up to 9 feet in diameter and over 75 feet in length

- Shell operating temperatures up to 2200 degrees F (1200 degrees C)

- Specific process atmospheres — inert, oxidizing, reducing, dehumidified

- Co-current and counter-current material/gas flow designs

- Multiple heating zone configurations

- Special materials of construction for high temperature and/or corrosive service