Thermal Processing Equipment

with a commitment to quality & reliability.

Heyl Patterson is known for pioneering engineered thermal processing solutions. Our thermal process equipment is used in industries around the world for process heating and cooling needs. From industrial rotary dryers and coolers, rotary calciners and fluid bed dryers and coolers, to specialized thermal processors, our products are highly-efficient in processing a wide range of materials.

Proven Process Solutions

From some of the largest rotary dryers, coolers, and calciners in the world to compact, high-capacity thermal processors, our thermal processing equipment efficiently handles powders, bulk solids, liquid sludges, thermally sensitive materials, combustible materials and more.

Dryers & Coolers

Our high-efficiency industrial dryers and coolers include the rotary dryer, which handles a broad range of materials, including liquid sludges, and our fluid bed dryer, which processes free-flowing bulk solids with maximum thermal efficiency. Flash dryers and coolers are also available.

Calciners

Capable of handling all calcining needs, our calciners feature high-temperature processing in a controlled environment with large throughput, electric or fuel heat transfer, zoned temperature control, chemical reactions, and thermal desorption.

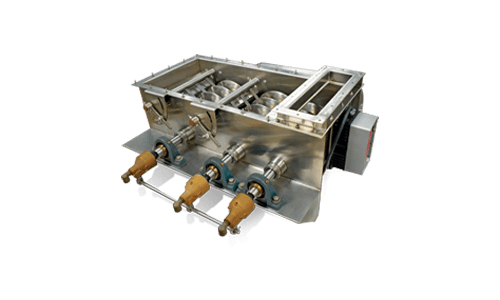

MultiDisc Thermal Processors

Our MultiDisc thermal processors deliver a cost-effective low or medium-temperature processing machine that utilizes an innovative conduction-convection heat transfer method with a high product-to-surface ratio to indirectly dry, heat, and/or cool a variety of products.

Product Testing Laboratory

Our Innovation Center provides material testing in a state-of-the-art laboratory setting. Testing your materials in our pilot plant testing lab can help determine the best technologies and equipment for your needs. The entire line of Heyl Patterson Thermal Processing equipment is available for testing. Customers can run tests on:

- Rotary Calciners

- Rotary Dryers

- Batch & Continuous Fluid Bed Dryers

- Flash Dryers

- MultiDisc Thermal Processors

Industries

Aftermarket Parts & Services

We offer a wide array of thermal processing parts and upgrades to support your equipment needs after purchasing processing equipment. Our services include inspection programs, field service, and engineering studies. These services are designed to identify potential issues before breakdowns. At Heyl Patterson Thermal Processing, our goal is to keep your equipment operating reliably and smoothly.