Chemical processes are at the heart of industrial applications, transforming raw materials into valuable products. But choosing between wet and dry chemical processes isn’t always straightforward. Each method has unique advantages and challenges, making it crucial to understand their differences and applications.

Key Differences Between Wet and Dry Chemical Processes

When comparing wet and dry chemical processes, several key differences can influence their suitability for various applications.

Medium of Reaction

Wet chemical processes use liquids, often water-based solutions, to facilitate chemical reactions. This can involve dissolving reactants or using liquid catalysts. Conversely, dry chemical processes rely on gases or solids to drive reactions, making them ideal for scenarios where moisture must be avoided.

Temperature Requirements

Wet processes generally operate at lower temperatures compared to their dry counterparts. This is because liquids often have lower boiling points and can act as heat sinks. Dry chemical processes, however, can reach much higher temperatures, which is beneficial for applications requiring high thermal energy.

Equipment and Infrastructure

The equipment used in wet chemical processes tends to be designed for handling liquids. This includes tanks, pumps, and piping systems that resist corrosion. Dry chemical processes require different setups, such as rotary calciners engineered to handle high temperatures and abrasive materials.

Efficiency and Control

Wet processes often allow more precise control over reaction parameters like concentration and pH levels, leading to consistent product quality. Dry processes offer efficiency in speed and energy use but may require more sophisticated control systems to maintain optimal operating conditions.

Environmental Impact

Wet chemical processes can generate wastewater that needs treatment before disposal, posing environmental challenges. Dry chemical processes typically produce less waste by volume but might release airborne particulates requiring filtration systems.

Understanding these differences is crucial when selecting the appropriate process for your specific industrial application.

Choosing the Right Process for Your Needs

Selecting the appropriate chemical process for your industrial application involves understanding your operation’s requirements and constraints.

Rotary Dryers & Coolers

Rotary dryers and coolers are versatile machines capable of handling various materials, including powder, bulk solids, and liquid sludges. These units can be customized to meet specific application requirements such as moisture content, drying air temperature, and retention time. They are ideal for processing hemp, biomass, fertilizers, and industrial minerals.

Fluid Bed Dryers & Coolers

Fluid bed dryers efficiently handle free-flowing materials like minerals, chemicals, plastics, and grains. These units fluidize materials in a rising air or gas flow, providing high heat transfer with gentle handling. Fluid bed dryers can be designed as trough-type or circular type and can include integral coolers to reduce material temperature after drying.

Flash Dryers & Coolers

Rotary dryers and coolers are versatile machines capable of handling various materials, including powder, bulk solids, and liquid sludges. These units can be customized to meet specific application requirements such as moisture content, drying air temperature, and retention time. They are ideal for processing hemp, biomass, fertilizers, and industrial minerals.

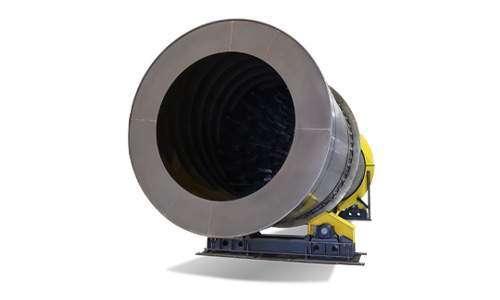

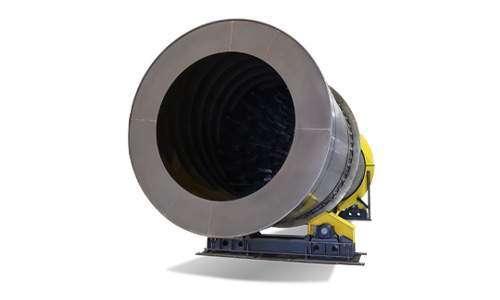

Rotary Calciners

Rotary calciners process fine and dusty materials sensitive to oxidation or combustible. These units use indirect heating to completely segregate the heat source from the product. They are ideal for processing catalysts, chemicals, hydrocarbons, activated carbon, yellowcake, PET flakes, biomass torrefaction, or carbonization.

MultiDisc Thermal Processor

The MultiDisc Thermal Processor indirectly drys or cools bulk solids using conduction-convection heat transfer. This unit offers high thermal efficiency, minimal exhaust gas volumes, and lower operational costs. Applications include grain processing, gypsum drying, organic chemicals treatment, pigment production, polyester processing, and soda ash production.

Heyl Patterson’s Expertise in Thermal Processing Solutions

Heyl Patterson Thermal Processing, founded in 1874 and a subsidiary of CPEG, brings over a century of expertise to the table. We provide reliable, versatile, and energy-efficient equipment tailored to various industries. Our engineers design custom solutions for processing biomass, chemicals, fertilizers, and minerals, ensuring optimal efficiency and effectiveness.

Ready to explore how Heyl Patterson can assist with your thermal processing needs? Request a quote today.

Last updated on December 22nd, 2025 at 01:02 pm