Rotary Calciners

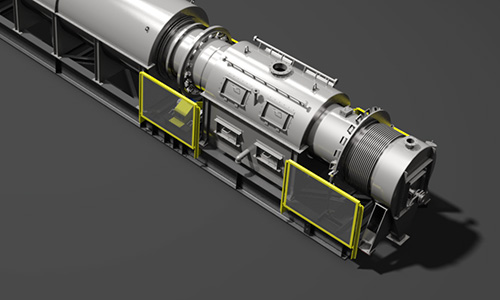

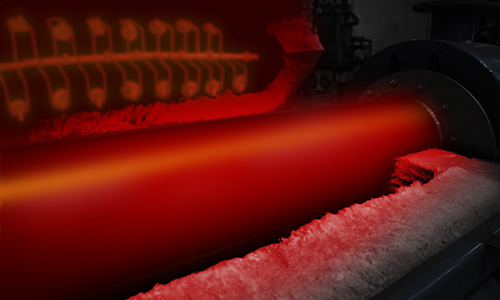

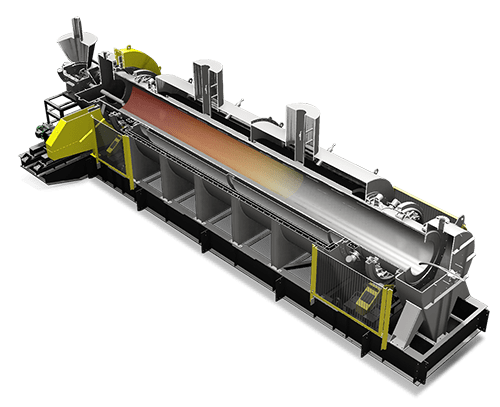

Transform materials with precision, efficiency & versatility. Heyl Patterson Rotary Calciners process hundreds of materials that are fine and dusty, sensitive to oxidation, combustible, explosive, potentially contaminating or thermally sensitive. Guaranteeing complete segregation of the heat source and the product through indirect heating, the Heyl Patterson Rotary Calciner is ideal for processing catalysts, chemicals, hydrocarbons, activated carbon, yellowcake and PET flakes, as well as for biomass torrefaction or carbonization.

With independent temperature control through heat zones, adjustable retention time, an enclosed rotating shell, and integrated coolers, Heyl Patterson calciners efficiently process materials in many industries.

Features & Benefits

- Multiple heat zones provide independent control for temperature profiling, such as ramp up, soak, and cool down.

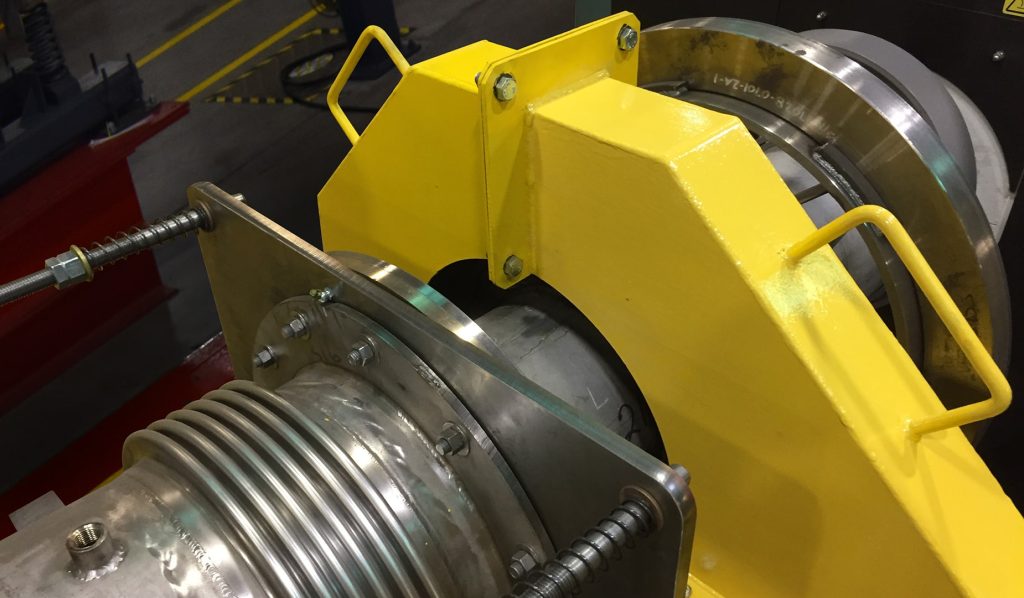

- Innovative seal designs for hazard mitigation.

- Custom-designed internal shell components provide maximum heat and mass transfer.

- Plug flow operation for product uniformity.

- Adjustable retention time for precise temperature and moisture control.

- Burners fire tangentially to eliminate localized overheating.

- Accurate bed temperature control with wireless telemetry for improved processing.

- Biomass Conversion

- Catalysts

- Ceramics

- Chemicals

- Fly Ash Beneficiation

- Lithium Ore

- Mining & Minerals

- Plastics

- Precious Metals

- Waste Conversion

Download our Rotary Calciners brochure to see more applications.

Advantages of Indirect Heating

With indirect heating, delicate materials are quickly processed, without excessive product entrainment in the gas stream. Requirements for emission control or volatile recovery can be reduced. Inert, oxidizing, reducing, and dehumidifying process atmospheres can be maintained.

Indirect heating also allows for process temperature profiling and eliminates contamination from the furnace exhaust to the material that is processed.

We also offer Fluid Bed Calciners when direct contact with the heating medium is desirable or required.

Specifications for a rotary calciner can be customized to a customer’s particular application, including:

- Sizes from 4 inches to 10 feet in diameter and lengths in excess of 100 feet

- Shell operating temperatures up to 2200 degrees F (1200 degrees C)

- Specific process atmospheres – inert, oxidizing, reducing, dehumidified

- Co-current and counter-current material/gas flow designs

- Multiple heating zone configurations

- Special materials of construction for high temperature and/or corrosive service

Built to your unique specifications, or designed by our engineers to exceed your specific application requirements, each Heyl Patterson Rotary Calciner can be rigorously pilot tested at our Innovation Center & Test Lab before the final design is implemented.

Speak to an expert.

Options & Accessories

- Rotary seals

- Integral coolers

- Drive systems

- High-temperature designs

- Burner & temperature systems

- Automatic lubrication systems

Featured Resource

This white paper discusses processing with Heyl Patterson calciners, from performance to zonal arrangements for temperature profiling.

Rotary Calciners FAQs

What’s the difference between direct and indirect calcination?

Direct calcination involves combustion gases in contact with the material; indirect calcination uses a heated surface or a heat-transfer medium to avoid gas contact. Indirect calcination is preferred for high-purity or sensitive materials.

How do I choose the right calciner size and temperature profile?

Sizing and temperature setpoints depend on throughput, the desired chemical change (e.g., phase transition), and reaction kinetics. Material testing provides critical data to determine optimal residence time and zone temperatures.

Are calciner systems customizable for controlled atmospheres?

Yes. Calciners can be configured for oxidizing, inert, or reducing atmospheres depending on whether you need to prevent oxidation, remove volatiles, or preserve specific properties.

How does rotary calciner design contribute to uniform heat distribution?

Rotary calciners use internal flights and controlled rotation to lift and cascade material, exposing it evenly to heat. This minimizes temperature gradients and ensures consistent product quality.

What safety considerations are typical with high-temperature calciners?

Safety features include temperature interlocks, robust sealing for controlled atmospheres, explosion vents where required, and effective monitoring for off-gas composition and flow.

Can calcination be combined with drying in a single system?

Yes, combination dryer/calciner systems are often used to reduce footprint and improve thermal efficiency, especially when moisture removal and thermal reaction are sequential steps.