Biomass Processing & Conversion

We offer advanced thermal processing equipment that ensures energy efficiency and reliability at every stage of biomass conversion. Renewable energy sources like biomass are gaining traction as the world shifts away from fossil fuels to reduce carbon footprints. Biomass, unlike fossil fuels, can be a carbon-neutral energy source when organic materials are replenished through replanting or farming. This sustainable energy solution is versatile and capable of generating heat and producing electricity, or it can be converted into liquid fuels for vehicles and power generators. When done correctly, biomass energy production can mitigate the negative impacts associated with fossil fuel refining, such as ecosystem damage.

Biomass energy is chemical energy stored in plants and animals from the sun. It can be sourced from dedicated energy crops, agricultural waste, human sewage, animal manure, municipal solid waste, and wood processing by-products. Biomass energy production mimics fossil fuel processes but relies on sustainable practices that remove carbon from the atmosphere. The conversion of biomass into energy involves four main processes: direct combustion, thermochemical conversion, chemical conversion, and biological conversion. Each method offers unique pathways to transform biomass into usable energy, from burning organic matter for heat to producing biodiesel through chemical reactions. These processes highlight biomass’s potential as a sustainable and versatile energy source.

Our commitment to cutting-edge technology and sustainable practices positions us at the forefront of the biomass sector. Our experienced engineers and professionals excel in custom-engineering machinery such as rotary calciners, rotary dryers, fluid bed dryers, and our multidisc thermal processor, all designed to handle biomass materials for sustainable energy production.

Thermal Processing Equipment for Biomass Energy Conversion

Get In Touch Today.

Upgrade your biomass processing system with Heyl Patterson’s innovative solutions. Contact our team to discover more about our advanced technologies and how we can help meet your business goals.

Rotary Calciners

Our rotary calciners are designed to handle biomass processes with combustible, oxidation-sensitive, or heat-sensitive materials. They separate the heat source from the material, making them perfect for turning biomass into charcoal or conducting torrefaction to convert biogas into a coal alternative.

Specifications

- Constructed from materials to withstand high temperatures and corrosion

- Gas flow designs for same or opposite direction airflow

- Operates at temperatures up to 2200°F (1204°C)

- Sizes available over 100 feet (30.48 meters) in length and up to 12 feet (3.6576 meters) in diameter

- Configurations available for various heating zones

- Suitable for dehumidified, inert, oxidizing, or reducing atmospheres

Rotary Dryers

Our rotary dryers are versatile and can handle a variety of feedstocks for processing biomass bulk solids. Manufacturers can set parameters like moisture content, biomass temperature, and retention time, with options for cooling either externally or internally (with integrated cooler design).

Specifications

- Airflow systems include forced-draft, induced-draft, or combined options

- Compatible with various control systems

- Lifting flight design for efficient conveying and drying

- Gas flow designs for same or opposite-direction airflow

- Operates with inlet gas temperatures up to 2200°F (1204°C)

- Sizes over 100 feet (30.48 meters) long and up to 16 feet (4.8768 meters) in diameter

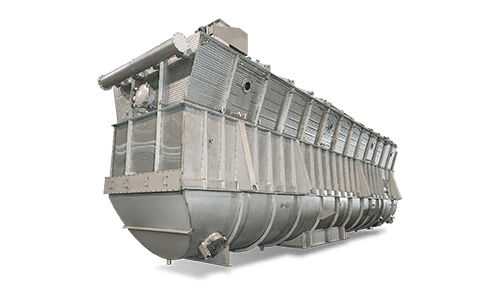

Fluid Bed Dryers

Our fluid bed dryers efficiently handle free-flowing biomass materials using an energy-saving fluidizing method to improve heat transfer rates. Fluid beds are highly efficient compared to other dryers. They come in circular, trough-type, or vibrating designs, providing flexible solutions for biomass processing.

Specifications

- Supports various control systems

- Cylindrical design option for back-mixing with continuous or batch flow

- Options for processing lumpy, sticky materials

- Features stainless steel or high-temperature alloy bedplates

- Handles inlet gas temperatures up to 2200°F (1204°C)

- Available in diameters up to 18 feet (5.4864 meters)

Explore Our Range of Equipment

Heyl Patterson offers a wide range of thermal processing equipment, including rotary calciners, fluid bed dryers, rotary dryers, industrial dryers, and thermal processors. We are dedicated to excellence and ensure that each piece of equipment is designed to enhance your biomass processing capabilities.

Biomass & Biofuels

Why Choose Us?

Biomass feedstocks vary in moisture, making drying and/or calcining a critical step in the conversion process. Heyl Patterson manufactures a variety of high-quality equipment tailored to processing biomass.

Product Testing

Product testing can be performed at the CPEG Innovation Center and Test Lab with your product sample using our process equipment.

- Experience: Includes activation, carbonization, torrefaction, biochar, conversion, and more.

- Equipment: Our equipment is customizable, dependable, and versatile.

- Application-Designed: Our equipment is specifically designed for your application.

- Support: Access to our team of experts each step of the way.