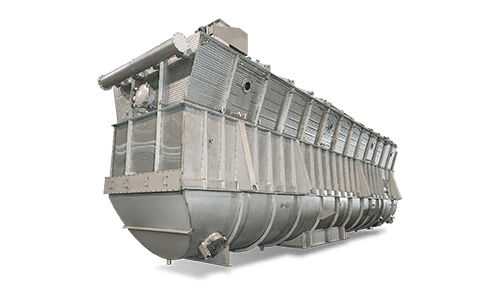

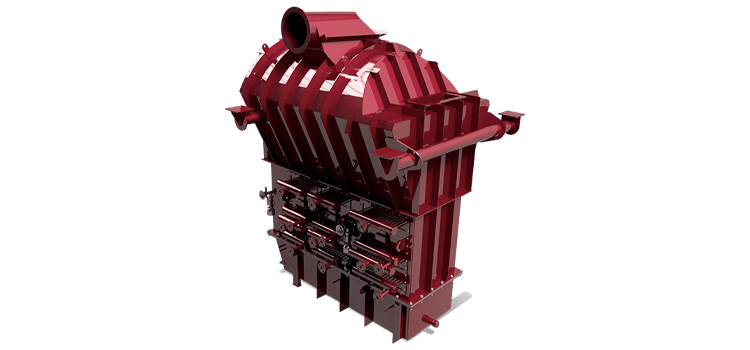

Fluid Bed Dryers & Coolers

Heyl Patterson Thermal Processing manufactures some of the largest and most efficient Fluid Bed Dryers in the world for free-flowing materials such as minerals, chemical, plastics, hemp & wood products, grains and waste. Materials are suspended in a rising flow of air or gas using an energy efficient fluidizing method that causes the material to act like a fluid which provides a high rate of heat transfer while gently handling the solids. It also provides lower capital equipment and operating costs as a result of its efficiency.

Particle size distribution and density, starting and final moisture content, product and drying air temperature, air velocity, and retention time of the material will be considered in selecting your dryer.

Features & Benefits

- The fluidizing design provides maximum heat utilization for drying gas steam for high thermal efficiency.

- A cylinder design provides back-mix flow, and a rectangular design provides plug flow.

- Completely pneumatic fluidization with no moving parts provides low maintenance.

- Fluidized media design efficiently processes sticky, lumpy, or otherwise hard-to-handle materials.

- Sizes up to 18 feet in diameter or equivalent rectangular configuration for large throughput.

- Inlet gas temperatures up to 2200 degrees F (1200 degrees C).

- Stainless steel or high-temperature alloy bedplate or refractory brick dome design.

- Coal

- Coke

- Dried Distillers Grains (DDG)

- Metallurgical Ores

- Plastics

- Rubber

- Hemp & Biomass

Heyl Patterson designs fluid bed agglomerator granulators for processing powder and bulk solids into spherical pellets. Fluid bed units typically combine drying with particle agglomeration or granulation by spraying the wet feed material onto a bed of seed material.

Fluid Bed Designs

Offered in three types, Trough-Type Fluid Bed, Circular Type Fluid Bed, and Vibrating, each unit can incorporate a standalone or integral cooler to reduce the material temperature after drying.

Trough-type employs a first-in/first-out plug flow method of product handling. Circular-type fluid beds have the advantage of back-mixing processed material with wet or sticky feeds to achieve uniform flow.

We also offer Rotary Dryers & Coolers and Flash Dryers & Coolers for our customer’s other specifications.

Conventional designs are available for powders and granular materials, as well as unique designs for materials which exhibit characteristics not normally conducive to fluid bed processing, such as sludges, filter cakes, agglomerates, and more.

- Designed as standalone units or in combination with dryers / coolers

- Small footprint compared to other drying and cooling technologies

- Completely pre-piped and pre-wired NFPA-approved burner valve trains

Built to your unique specifications, or designed by our engineers to exceed your specific application requirements, each Fluid Bed Processor can be rigorously pilot tested at our Innovation Center & Test Lab before the final design is implemented.

Speak to an expert.

Options & Accessories

- Combined drying/cooling

- Through air swept design

- In-bed plate or pipe coils

- Evaporative water spray design

- Abrasion & corrosion-resistant designs

- PLC control systems